Robotier Robotic Palletizer cells Robotic palletizer

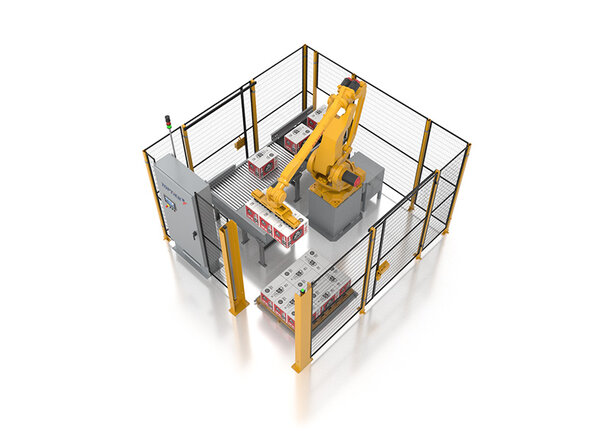

Robotic palletizer cells offer wide layout flexibility and are engineered from experience

Configuration Available

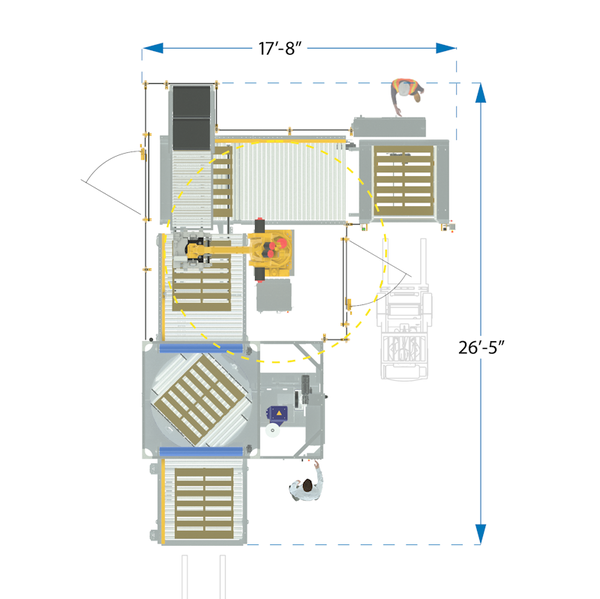

Fully-Automatic > 1-in 1-out > Stretch Wrap Robotic Palletizer cells

|

|

|

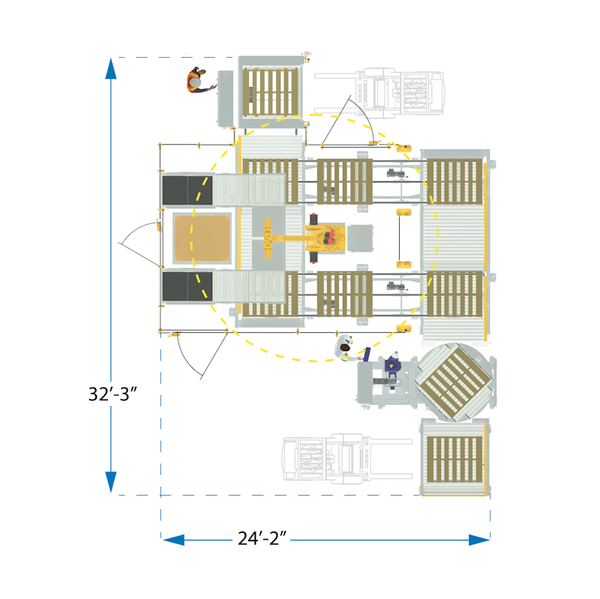

Fully-Automatic > 2-in 2-out > Stretch Wrap Robotic Palletizer cells

|

|

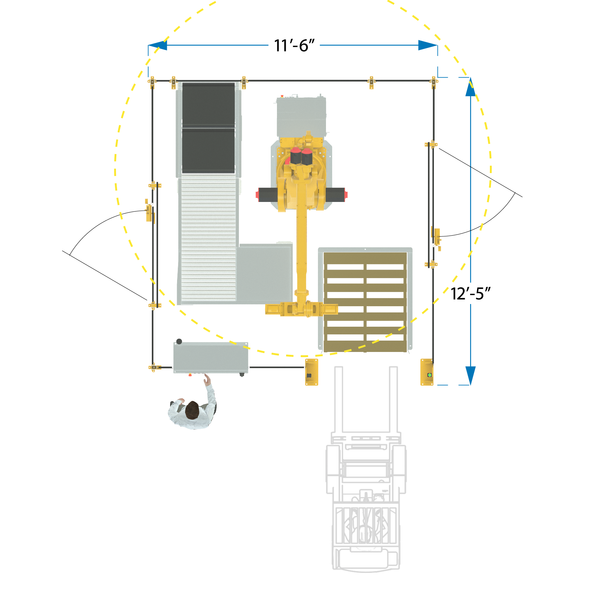

Semi-Automatic > 1-in 1 out Robotic Palletizer cells

|

|

|

product benefits

Case Dimension

Minimum 6" Maximum 29" Maximum Weight: 220lbs

Infeed Height

23" to 60"

Products

Case, bag, bundle, display tray, and more

Safety Rating

Cat 3

Key features

HMI:

AB Panelview 5310 10” Color Touchscreen

Robot:

Fanuc

Stretch Wrapper:

Robopac Automatic

Conveyor:

TopTier MDR and Pallet Conveyors

Allen Bradley controls

Higher speed configurations PLC’s and VFD’s

Safety:

Category 3

overview

TECHNOLOGY

RoboTier utilizes end of arm tooling that supports product from the bottom, allowing higher speed robot motion and advanced product handling security. Bottom support offers a significant improvement over typical robot product handling methods such as vacuum top picking that is less flexible and secure, and clamping systems that necessitate looser loads.

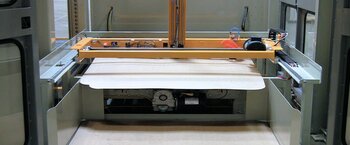

Bottom support is achieved by assembling layers on an apron with products loosely spread to allow removal of the bottom support tool. Loose spreading allows faster robot speeds, as exact product placement is not critical. Once a layer is completed, four-sided clamping centers the layer on the pallet and a tight uniform layer is deposited. Vertical travel capabilities of the apron reduce robot reach requirements allowing use of the smaller, faster, and more economical Fanuc robots. The layer apron also provides a queuing platform for continued layer building while optional concurrent stretch wrapping occurs.

CONTROLS

RoboTier product handling innovations are enhanced by advanced controls architecture for robotic palletizing systems. A Fanuc controller with very simple code that cannot be modified directs robot motion based on PLC instructions. In effect, the robot is an electronic slave to the Allen Bradley CompactLogix PLC master controller and B&R PC 12" color touchscreen HMI. All automatic and manual palletizer functions are controlled using the HMI touchscreen; robot controls training or experience is unnecessary. EasyStack programming software installed on the PC HMI creates patterns quickly and easily without PLC or robot programming.

Robotier Robotic Palletizer Cells from TopTier palletizers

option & data sheet

Pallet Handling

Empty pallet handling consists of a pallet dispenser and systems to position a pallet at the load build. Pallets used by in industry vary in quality, height and design. Empty pallets are difficult to reliably transport due to inconsistencies in the pallet bottom. Pallet handling system positively position and square empty pallets using pusher systems and the pallet dispenser is a universal lift and separate design using forks to reliably support the pallet stack.

Concurrent Stretch Wrapping

TopTier is the global leader in concurrent stretch wrapping technology. Concurrent wrapping saves floor space and lowers overall end-of-line costs. New patented features save film and insure continuous palletizing operations.

Load Handling

Automated load exit is available with pallet conveyor of any length required for load accumulation.

Sheets handling

TopTier offers comprehensive sheet handling capabilities. Freezer separator sheets that facilitate air flow are handled. Sheet insertion equipment is used to place an empty pallet onto a half load allowing double stack loads.

Features

Pallet liners are inserted with a horizontally travelling vacuum pick and place device

Tie sheets, freezer sheets, slip sheets, and top caps are inserted with a vertically and horizontally travelling vacuum pick and place device capable of placing a sheet at any level of the load

Sheets inserted at load build position for unitized loads

Tie sheet inserters can be equipped with up to three pick positions allowing separate sheet styles

Low Infeed: Sheets are loaded into a 18" capacity drawer and safely loaded during palletizer operations

High Infeed: Sheet inserter mounted above or at mezzanine level. The mezzanine level device is manual loaded with up to 18" of sheets with one or two bins available. Bins may be loaded at ground level and positioned with a forklift. Optional lift device is available to raise sheet stack to the upper level position.

Sheet bin loading with no interruption of operations

Sheet size less than 60" in either dimension including 2, 3 or 4 tab models

Capacity of 18" of sheets

Tall Loads

Tall Loads

Maximum load height of 108" is available

Heavy Loads

Maximum layer weight of 1000lbs is available

Freezer

Our solutions are available for use in the low temperature environments (14 F).

Load Labeling

Labels are applied on from 1 to 4 sides of the load.

For multiple palletizer configurations, labels may be applied at a single common station.