Elevate your palletizing experience with a range of optional features to suit your specific needs.

Our palletizer options provide the flexibility and precision your operation demands.

In today's demanding manufacturing landscape, efficiency and precision in palletizing operations are paramount. TopTier's pioneering palletizer options address these needs with advanced features designed to enhance productivity and adaptability in the fast-paced manufacturing industry.

You can achieve unparalleled accuracy and consistency with our automated load labeling system. Labels can be effortlessly applied from one to four sides of the load, optimizing identification and tracking for downstream processes. For facilities utilizing multiple palletizer configurations, a centralized labeling station streamlines the process while ensuring uniformity across all units.

Our palletizer options also include multi-palletizer shuttles. At TopTier, each innovative shuttle mechanism provides a cost-effective solution for multi-palletizer configurations. A fully automated single car handles both the delivery of empty pallets and the retrieval of completed loads, thereby maximizing return on investment and space utilization within the facility.

Beyond our multi-pallet shuttle system, we also have automated pallet handling systems available for manufacturers. Learn about these systems and more below to find the best palletizing solution for your business.

Automated load exit is available with pallet conveyor of any length required for load accumulation.

Labels are applied on from 1 to 4 sides of the load.

For multiple palletizer configurations, labels may be applied at a single common station.

Shuttles are a cost effective option on multiple palletizer configurations.

A fully automated single car can both deliver empty pallets to and retrieve completed loads from each palletizer.

Pallet dispenser provides safe and secure single pallet release

Empty pallet handling consists of a pallet dispenser and systems to position a pallet at the load build.

We uniquely engineered our automated pallet dispenser to handle a wide range of pallet sizes and designs commonly found in the consumer packaged goods (CPG) industry. This adaptability ensures seamless integration into existing workflows, providing a smooth and reliable operation that minimizes downtime and maintains steady production flows.

Pallets used by the CPG industry vary in quality, height and design. Empty pallets can be difficult to reliably transport due to inconsistencies in the pallet base. To help compensate for irregularities in pallet quality TopTier offers three different styles of pallet dispensing each with a “lift and separate” design to reliably support the pallet stack. The most commonly used dispenser is designed for 4-way entry 40x48 pallets only. TopTier offers two other designs to accommodate multiple pallet dimensions and styles.

Features / Options*

- Empty pallet pushing and squaring of the empty pallet in the load build

- Forks extend and retract into the pallet opening to accommodate 2-way entry pallets

- Light curtain protection of dispenser load position

- Empty pallet loading does not impact palletizer operations

- 12 to 20 pallet capacity

*Features and options described are application specific.

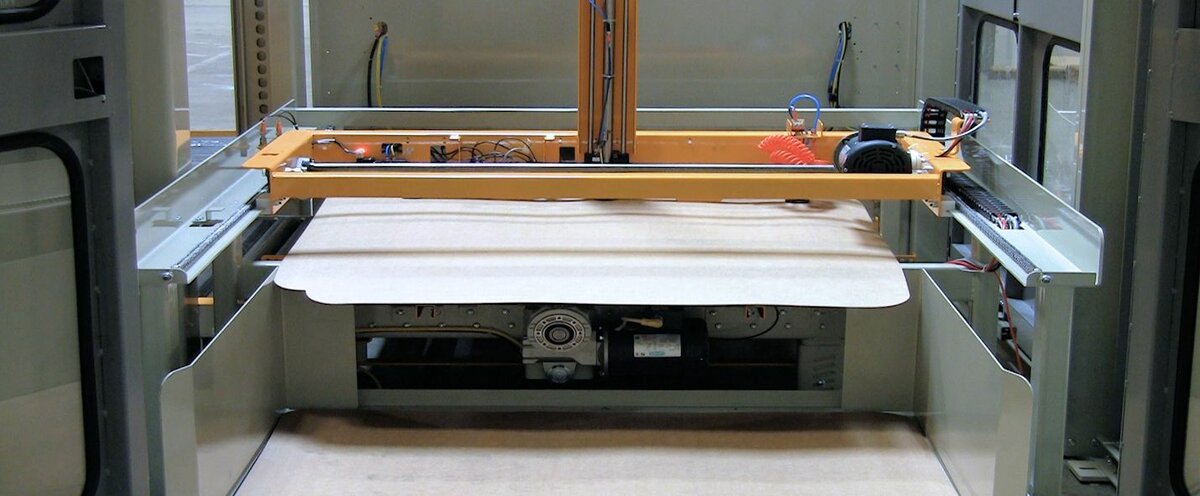

Pallet Liner Sheets

Palletizing is an essential process for many industries, as it allows for the safe and efficient storage and transportation of goods. However, without proper planning and materials, palletizing can easily become a time-consuming and costly task. That's where pallet liner sheets come in. TopTier palletizers can place specialized sheets that provide a protective layer between products and pallets, ensuring stability and preventing damage during handling and transportation. Here at TopTier, we understand the importance of reliable palletizing. That's why our machines can strategically place high-quality pallet liner slip sheets and tie sheets for pallets.

Sheets are used as pallet liners, slip sheets with tabs, or tie sheets and top caps

TopTier offers comprehensive sheet handling capabilities. Freezer separator sheets that facilitate air flow are handled. Sheet insertion equipment is used to place an empty pallet onto a half load allowing double stack loads.

Features

- Pallet liners are inserted with a horizontally travelling vacuum pick and place device

- Tie sheets, freezer sheets, slip sheets, and top caps are inserted with a vertically and horizontally travelling vacuum pick and place device capable of placing a sheet at any level of the load

- Sheets inserted at load build position for unitized loads

- Tie sheet inserters can be equipped with up to three pick positions allowing separate sheet styles

- Low Infeed: Sheets are loaded into a 18" capacity drawer and safely loaded during palletizer operations

- High Infeed: Sheet inserter mounted above or at mezzanine level. The mezzanine level device is manual loaded with up to 18" of sheets with one or two bins available. Bins may be loaded at ground level and positioned with a forklift. Optional lift device is available to raise sheet stack to the upper level position.

- Sheet bin loading with no interruption of operations

- Sheet size less than 60" in either dimension including 2, 3 or 4 tab models

- Capacity of 18" of sheets

These sophisticated systems underscore TopTier's commitment to providing innovative solutions that address the dynamic needs of all industries. With improved reliability and efficiency, each palletizing system is an invaluable asset for any operation looking to optimize its palletizing process.

In the competitive realm of the food, beverage, and other industries, businesses require reliable solutions to maintain a seamless flow within their logistical pipelines. TopTier's high-quality palletizer options deliver unparalleled efficiency, adaptability, and operational excellence, marking the beginning of an elevated palletizing experience. Elevate your workspace with cutting-edge palletizing equipment from TopTier to discover how our palletizing solutions can transform your operations.